Siewekeweg 8 · 33758 Schloß Holte-Stukenbrock · Tel. +49 5207 88980-20

Fax +49 5207 88980-19 · E-Mail: info@peitzmeier-maschinenbau.de

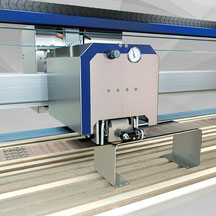

omni-grind dura

OMNI-GRIND is a Modular System, which allows an individual configuration of the Grinding Machine exactly for your processing. Available are Modules for grinding, polishing, deburring and for beveling your parts. In addition to this, the Handling of the Machine is also configurable, from manual drive of the table and tools to programmable and automatic machining of your parts. The control and all modules are retrofittable at any time.

High-Performance Long-Belt-Grinding-Machine for the efficient grinding of large and also heavy metal plates.

- Two powerful 15 kW grinding Units with two belts on the front and rear for 160 mm wide grinding belts

- Fast and parallel processing of large surfaces

- Automatical movement of the tool

- Programming by a BECKHOFF Industry PC with 15,6" Touch Panel

- Easy control and Teach-In with graphic menu based on Twin-Cat and/or intelligent Hand-Wheel for set up

- Table width from 3 to 12 m

- Table Depth from 3 to 15 m

- Height adjustment up to 1,5 m

- Workpiece weight up to 40 t

Features omni-grind dura

Solid Machine Design

very stiff and solid frame by FEM

Ergonomic Design

straight shape with integrated Drive Systems for easy cleaning and less maintenance

Deburring and Edge Rounding Unit

4,4 kW fullautomatec with brushes ∅ 260 mm

Polishing Head 3 kW

frequency-controlled and fully automated feed forward

Modular Control System

based on the Software TWIN-CAT from BECKHOFF allows the Manual, semi- or total automated handling of the machine

Mobile Control Unit

setting and teach-in very easily and accurately with the jogwheel of the mobile Control unit

Contact-Drum automated

Flexible Clamping Devices for different weights of your parts

Handling Device <80 kg

Table 200-500 kg

Swivelling Devices 350 - 700 kg

6-Axis-Shortarm Robot

for automated grinding and handling of rounded parts